Cost-Effective, High-Performance Variable Frequency Drive Solutions for the Smart Upgrade of White Goods

2024-06-06

In the consumer electronics industry, white goods have long been essential, playing a crucial role in improving the quality of life for households. However, challenges such as product homogenization, slowing market growth, and consumers' increasing expectations for energy efficiency, environmental friendliness, and smart features have led to a period of stagnation in the white goods industry. In response, manufacturers have proactively adapted in recent years, vigorously implementing strategies to enhance quality, reduce costs, and improve efficiency. Among these efforts, the widespread adoption and continuous advancement of variable frequency technology are seen as effective pathways to help the white goods industry break through bottlenecks and move toward higher standards and sustainable growth.

Under these circumstances, variable frequency home appliances not only align with global energy conservation and emission reduction efforts but also precisely meet consumers' growing demand for high-efficiency appliances. Furthermore, they play a pivotal role in advancing the industry's green transformation and enhancing the living experience of households. In variable frequency compressor systems, the microcontroller unit (MCU), which acts as the "central nervous system," is equally critical in shaping the core competitiveness of the variable frequency appliance market.

Smart Drives: Redefining Home Appliance Excellence

Variable frequency technology has excelled in applications such as precise washing speed control in washing machines and intelligent temperature management in refrigerators. It not only significantly enhances user comfort and convenience but also leaves a distinct "green footprint" in terms of energy consumption. Additionally, with lower startup noise and vibration, it contributes to a higher-quality user experience. The key lies in the precise control of the compressor drive system, effectively avoiding the high energy consumption issues caused by frequent start-stop cycles or prolonged high-load operation in traditional fixed-frequency devices.

In fact, consumers' core demands for variable frequency drives in home appliances—low startup noise, small startup current, and fast startup response—are underpinned by key technologies such as variable frequency control and drive algorithms. These innovations have added new values to home appliance semiconductor components with new value. As the command center of the variable frequency system, the MCU is responsible for receiving and interpreting various input signals, such as user-set parameters, sensor data, and communication commands. Based on this information, it calculates the optimal motor control strategy in real time, including fine-tuning key parameters like voltage, frequency, and phase. This ensures that home appliances achieve significant energy savings while maintaining performance.

For high-end variable frequency home appliances, the MCU not only fulfills basic control functions but also plays a critical role in enhancing the device's intelligence. For instance, as modern appliances incorporate features such as remote monitoring, self-diagnosis, and autonomous adjustment to meet consumers' demands for convenience and personalized experiences, the MCU leverages its powerful data processing capabilities, extensive communication interfaces, and highly flexible programming features to seamlessly integrate various intelligent modules. This enables real-time control and smart connectivity for complex systems, dynamically optimizing variable frequency strategies. Examples include automatically adjusting air conditioner fan speed based on room temperature or pre-setting the optimal washing program according to fabric type, making home appliances both smarter and more user-friendly.

On the other hand, the home appliance market has always been price-sensitive. Amid intensifying competition in product differentiation, how to provide customized solutions that help white goods manufacturers quickly achieve product differentiation and stand out in the competitive market is a key focus for every MCU supplier.

Cost-Effective Performance: High-Quality Drives for Refrigerators

GigaDevice, a prominent leader in the microcontroller (MCU) market, provides comprehensive, end-to-end solutions to drive innovation and upgrades in the home appliance industry, ranging from component selection and development support to reference designs and mass production solutions. MCU series such as GD32E230xx and GD32F3x0 can equip refrigerators, washing machines, and other white goods with a powerful and agile "variable frequency core." For example, the washing machine variable frequency drive solution based on GD32E230xx addresses the technical challenges of both pulsator and drum washing machines, achieving new breakthroughs. It supports advanced features such as dual-resistor sampling for noise reduction, IPM dead-zone compensation for low-speed washing, field weakening for high-speed drum/pulsator driving, fast and reliable startup, load weighing, braking, imbalance detection, and dehydration protection.

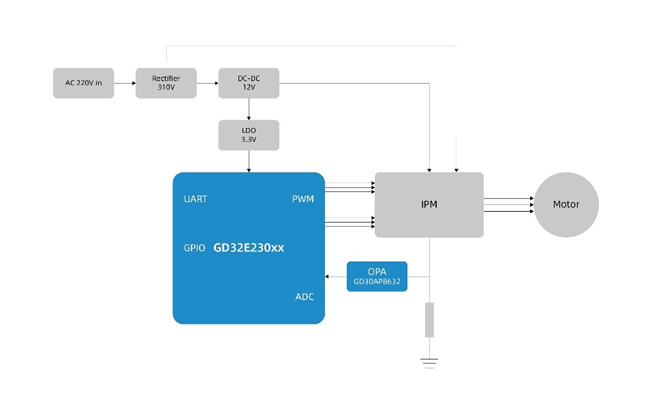

For refrigerator variable frequency applications, GigaDevice, in collaboration with its partners, has developed a turnkey variable frequency drive solution based on the GD32E230xx series MCU. Leveraging exceptional hardware performance and advanced control algorithms, this solution demonstrates strong market competitiveness. The GD32E230xx series MCU, built on the ARM® Cortex®-M23 core with a maximum operating frequency of 72MHz, delivers higher computational efficiency while maintaining ultra-low power consumption compared to Cortex®-M0-based counterparts in the market. This is crucial for the long-term stable operation and excellent energy efficiency of white goods variable frequency systems.

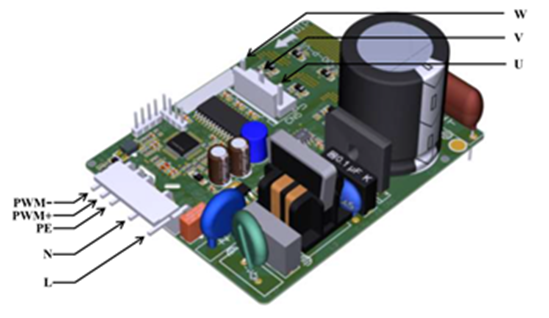

This variable frequency drive solution utilizes advanced circuit design and PCB layout techniques, enabling a unified PCB design for power ranges from 100 to 250 watts. This significantly enhances product versatility and reduces structural design and maintenance costs. A unique feature of this solution is the separation of compressor drive control parameters from the application software. When users replace a compressor, only the control parameters need to be updated, eliminating the need for changes to the electronic control or drive hardware. Currently, the solution widely supports various mainstream compressor models and offers professional customization services to meet personalized needs.

In compressors, lubricating oil plays a critical role in lubrication, noise reduction, efficiency improvement, and oxidation resistance. A standout feature of this drive solution is its built-in intelligent oil return platform function—after startup, the drive system automatically guides the compressor into a preset oil return speed range, effectively reducing the complexity of the main control board software and simplifying system programming. Additionally, the solution leverages advanced frequency-hopping technology, allowing users to preset specific frequency-hopping points to actively avoid frequency ranges that may cause resonance. This prevents mechanical vibrations, increased noise, and potential equipment damage caused by resonance, ensuring smooth and risk-free system operation.

Durability and reliability are another key consideration for consumers when choosing home appliances. This variable frequency drive solution is designed in strict compliance with UL standards and has undergone comprehensive, multi-dimensional testing (voltage, current, environmental, and load conditions) exceeding real-world application requirements to ensure top-tier quality. It is also equipped with a wide range of protection features, such as overcurrent, overvoltage, overtemperature, overpower, phase loss, and stall protection. Critical protections, like output overcurrent protection, adopt a dual hardware-software protection strategy.

Software algorithms serve as the control strategy and logical core of hardware systems. In addition to outstanding hardware performance, this solution employs a high-performance digital signal processor, single-resistor current sampling, and extended back-EMF sensorless vector control algorithms to ensure efficient operation of the drive system. Furthermore, the unique hybrid pulse-width modulation (PWM) technology reduces switching losses by 50% compared to traditional continuous PWM techniques, enhancing overall operating efficiency of the drive while balancing noise and efficiency. Thanks to GigaDevice and its partners' continuous R&D investment in variable frequency products, this solution has been successfully adopted by leading domestic home appliance manufacturers. Meanwhile, GigaDevice is actively developing next-generation MCU products tailored for white goods motor drives.

Collaborative Ecosystem: Full-Service MCU Solutions for Home Appliances

In fact, when selecting MCU suppliers, home appliance market customers not only evaluate their continuous innovation capabilities in new product development but also place great emphasis on their "soft" strengths. These include R&D investment, quality control capabilities, customized services, pre- and post-sales support throughout the product lifecycle, and stable supply assurance. In response, GigaDevice is actively building an MCU chip industry ecosystem tailored for white goods, and has already achieved significant results.

GigaDevice, in collaboration with global ecosystem partners, has established a comprehensive product ecosystem. This includes various integrated development environments (IDE), evaluation boards (EVB), real-time operating systems (RTOS), graphical user interfaces (GUI), security components, cloud connectivity, and embedded AI solutions. Additionally, the technical platform offers a wide range of video tutorials and short films for users to access online learning at any time. This rich development ecosystem not only provides tremendous convenience for home appliance manufacturers in their design processes but also reflects GigaDevice's product value and service philosophy.

In terms of product platform development, in addition to the GD32E230xx and GD32F3x0 series suitable for variable frequency drive systems, the GigaDevice GD32 MCU family also includes multiple categories such as the low-power GD32L series, the wireless connectivity GD32W series, and the ultra-high-performance GD32H series. These provide a wide range of product options for diverse home appliance application scenarios. For example, to address the growing demand for screen displays in smart appliances, the company's GD32H7 series MCUs are equipped with customizable smart human-machine interface (HMI) capabilities, supporting edge AI applications and meeting various human-computer interaction needs such as voice, gesture, and touch. Furthermore, GD32 MCUs are known for their industry-leading low failure rates, ensuring stable performance in complex and dynamic application scenarios. Their strong electromagnetic interference (EMI) resistance further enhances the operational stability of home appliances.

In addition, GigaDevice has established a rigorous quality management system, achieving closed-loop management across the entire chain of R&D, production, and supply. This ensures that the high standards of quality and after-sales service demanded by home appliance customers are met. GigaDevice has also formed strategic partnerships with leading wafer fabs and packaging and testing facilities worldwide. Leveraging a diversified supply chain system and flexible supply capabilities, the company effectively navigates market cycle fluctuations and reliably meets the procurement needs of home appliance customers.

As the intersection of market trends and technological innovation, frequency conversion technology for white goods has not only sparked a new trend in energy efficiency upgrades across the industry but also reshaped consumers' expectations for high-quality home appliances. The frequency conversion drive solutions built on GigaDevice's GD32 series of MCUs help customers accelerate their product launch timelines and enhance market competitiveness in a cost-effective manner.